Destro Serv Is the Most Advanced Technology for separating iron from slag

The Issue We Address

- Slag from blast and steel furnaces contains up to 20% of iron.

- Screened slag can be turned into valuable material.

- Conventional technologies fail in processing slag with metallic parts.

Our Solution

Destro Serv can crush, screen and separate up to 300 t per hour of slag with iron content. Without breaks and shutdowns.

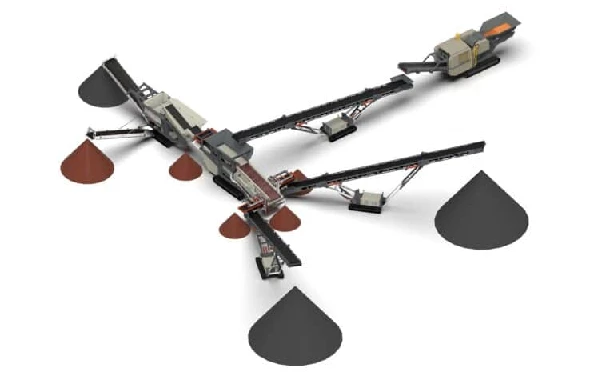

Destro Serv – a unique combination of 3 state-of-the-art machines working in amazing harmony

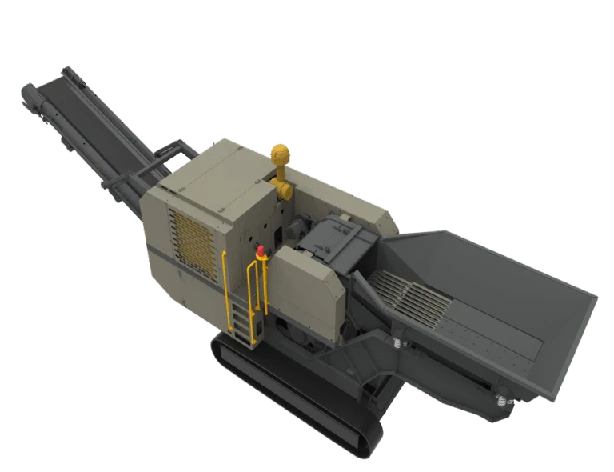

RAPTOR

the Crusher

A jaw crusher with tremendous power in sensitive palms.

More Info

A crusher with extraordinary power in the right hands

It has a unique patented construction, thanks to which the smooth passage of material with a high content of large non-crushable components is enabled. Even at the minimum gap adjustment, Raptor is resistant to tramp iron, excavator teeth, hammer heads, etc.

The unique Up trust Toggle Jaw crushing unit is the Raptor’s heart. It provides uniform particles of the crushed material, high resistance against blockages, longlife durability and extreme power. The gap releases up to 400 mm. Raptor is specially designed for slag crushing.

Technical Data

Crusher gap opening 30 - 400 mm (adjustable)

Crusher chamber release pressure 30 - 80 bar (adjustable)

Maximum passage of non-crushable parts 1100 x 400 mm

Feeding volume 4,5 m3

SAURUS

the Sorter

A clever magnetic sorter precisely tuned to each fraction.

More Info

A clever magnetic sorter precisely tuned to each fraction.

It sorts 4 fractions separately so that each route is precisely set for optimal efficiency. Thanks to this it achieves a high level of separation of the metal component.

Technical Data

Feed hopper with heavy duty vibrating feeder

4 bearing eccentric shaft screener type NIAGARA

Heavy duty end product conveyors with RIPSTOP belts

3 individual magnets to recover A/B/C scrap with hydraulic height & lengths adjustment for easy positioning magnets

Diesel engine 130 kW with AUX hydraulic to power 2 additional stockpile conveyors

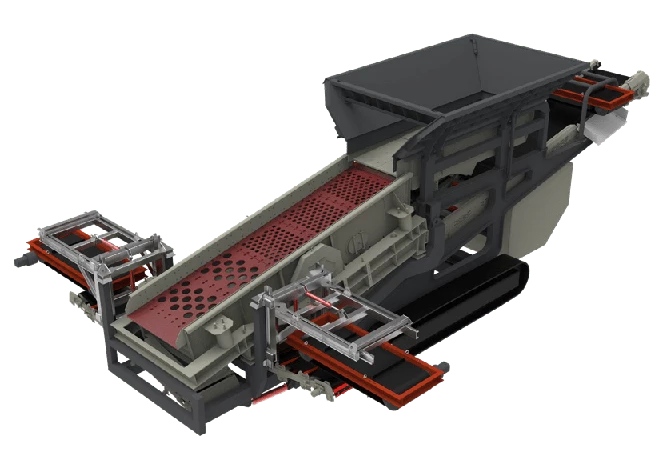

DINO

the Separator

A tunable magnetic drum separator with gentle fingers.

More Info

A tunable magnetic drum separator with gentle fingers.

Drum magnetic separation applied to the C scrap with the possibility of setting the purity of the output material thanks to varied setting of the speed and distance of the magnet.

Technical Data

Feedhopper size 6 m3

Belt feeder width 1200 mm

Distribution vibrating chute 1040 x 2174 mm

Magnetic drum size 900 x 2200 mm

Diesel engine 70 kW

The capacity of the entire factory is up to 300 T of Slag per Hour

- Available worldwide

Interested?

Send us your inquiry today. We will happily discuss the best way of processing your slag.

About Destro

Destro SlagCem is a family business and has as a partner Destro Kladno, a company since 1990 with a lot of experience in transforming waste into materials. Our headquarters are located in Călan, near Hunedoara, Romania. We process waste from iron and steel production and the construction industry and transform it into quality raw materials and products.

Our products meet the highest quality requirements and are environmentally friendly.

The quality of our products is regularly tested in independent testing laboratories.

Our customers are iron and steel mills, foundries, producers of cement and mortar mixtures, building companies and also small customers.

We also utilize our competencies in the form of waste treatment services in premises of our customers around the world.

We really value a healthy and pleasant environment. We believe that everything we do contributes to this core value.